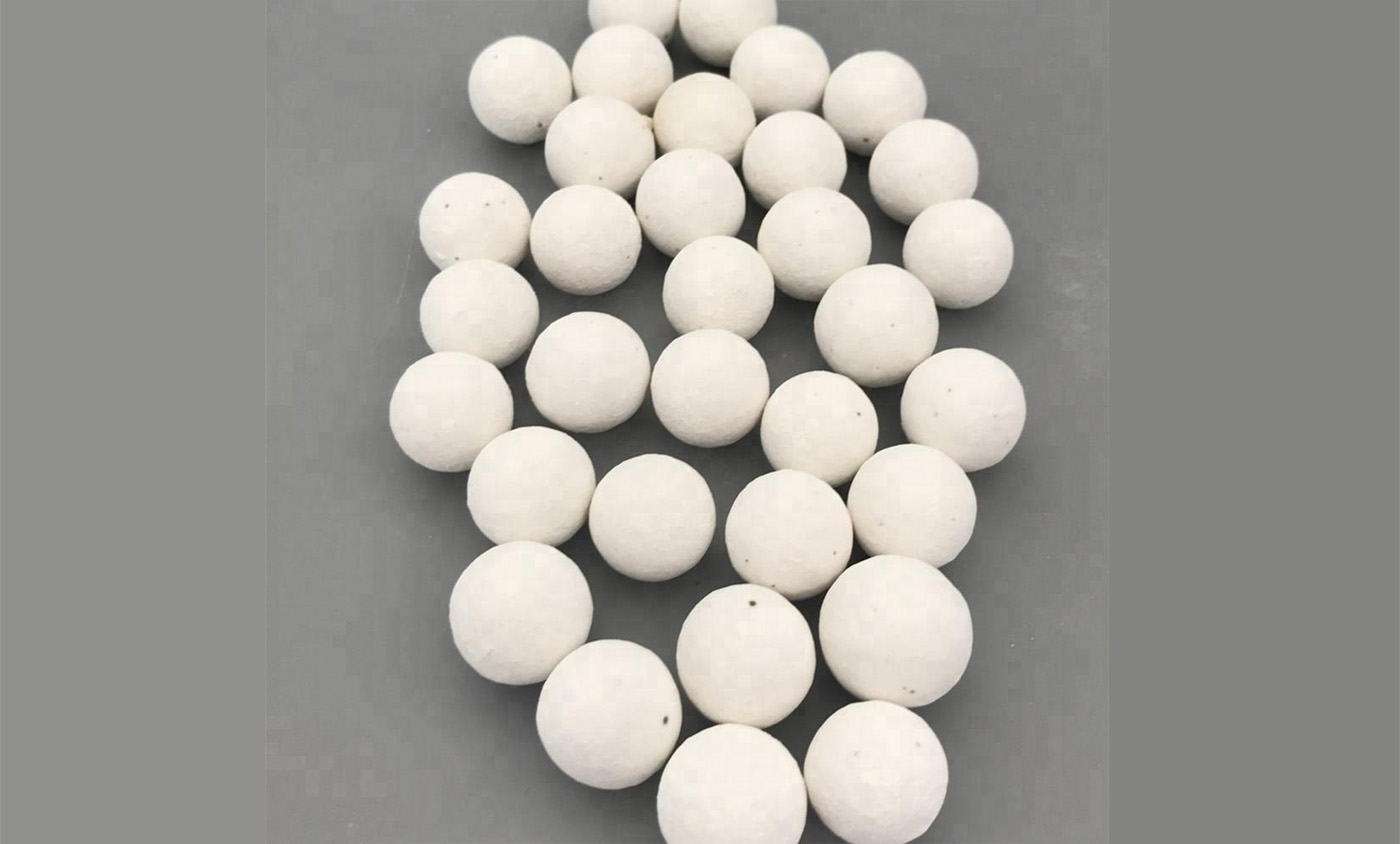

Ball mill is currently considered as an essential component in the process of preparing materials in various industries such as ceramic tiles, porcelain and glaze, paint and cement and powder making, but in all industrial ball mills, corrosion And the wear of the bullet and the body of the ball is a big problem and if the milled materials are sensitive to metal contamination, this problem becomes more pronounced, therefore in the ceramic, tile, porcelain and sanitary ware industries in ball mills The material of the bullets and the body (liner) is ceramic in order to introduce the least pollution into the raw materials.

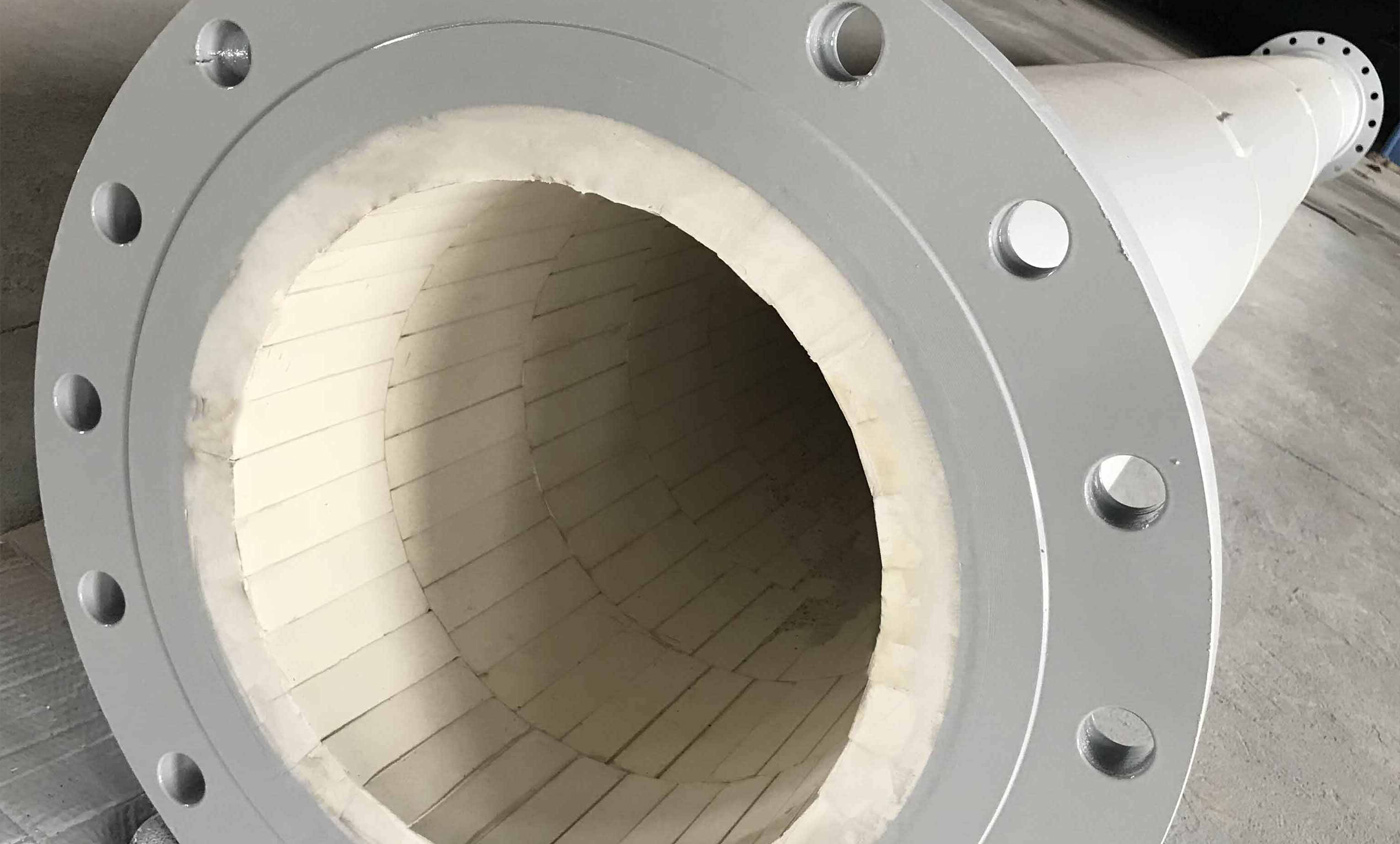

Anti-wear bricks:

Alumina-based ceramic liners with 92% ultra-wear-resistant alumina, the best choice for combating production line wear in steel mills, pelletizing, exploitation of iron ore inside the body of shots, dampers, classifiers, cyclones and all surfaces With wear.

Anti-wear bricks are one of the types of bricks that are widely used in industries such as steel or cement making. Because these bricks have a lot of resistance to high heat. Many manufacturers are active in the production of this product in Iran and always try to use the highest quality raw materials in the production of this product in order to provide the highest quality anti-wear bricks with the best quality to their customers.

In this article, we intend to examine anti-wear bricks from all angles:

Anti-wear bricks, due to their properties, are one of the most widely used and practical equipment in various industries, especially industries that deal with materials that always have anti-corrosion and anti-wear properties.

The reason for the anti-wear properties of bricks is that materials have been used in the production process of this product, which has made this brick highly resistant to very high temperatures.

In fact, it can be said that these types of bricks are considered as a category of ceramics because they have been glazed. In the glaze that is considered as a coating for these bricks, a material called alumina has been used, which is one of the main reasons. Increased resistance of these bricks to abrasion and heat. In fact, the percentage of alumina in anti-wear bricks is one of the characteristics that should always be considered.

The important point is that the characteristics of alumina and brick should always be the same, for example, the brick and alumina in its glaze should have the same coefficient of thermal expansion so as not to be damaged when placed in the furnace.

These types of bricks are divided into different types and sizes in terms of dimensions and size, each of which has different dimensions and size according to the operation intended for them.